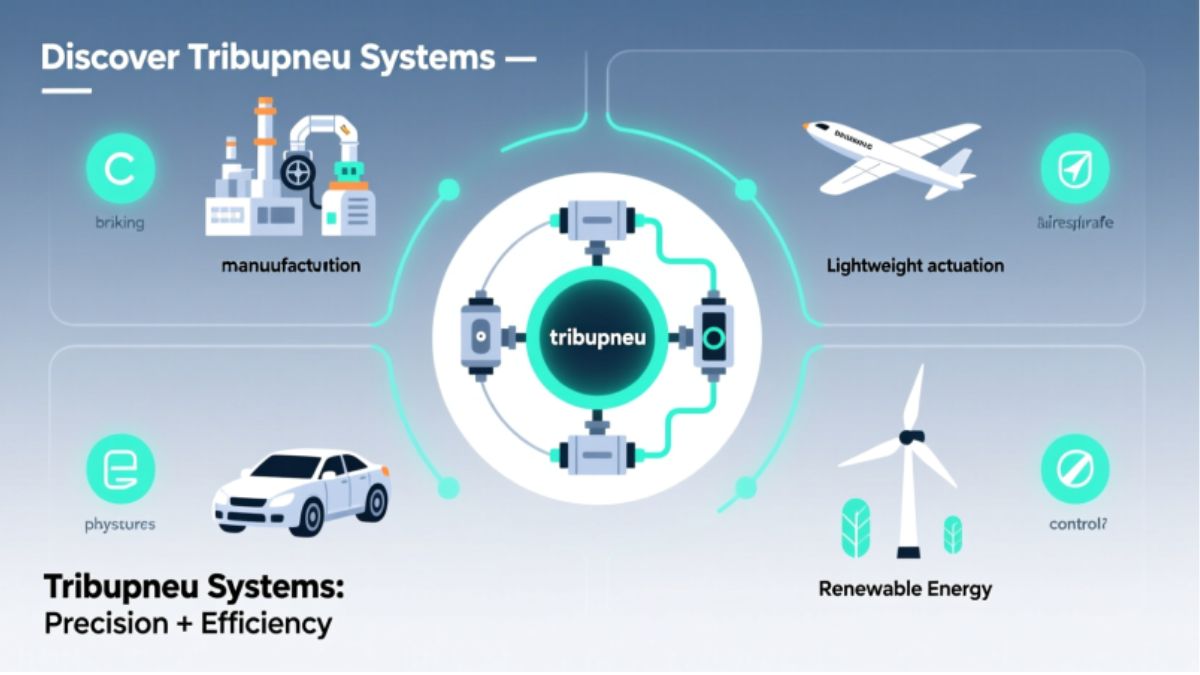

In today’s industrial world, the use of advanced technologies has become a crucial aspect of efficiency, safety, and productivity. Among these innovations, tribupneu systems have emerged as an essential solution for various applications, ranging from manufacturing to transportation. The term “tribupneu” may seem technical at first, but it fundamentally refers to a specialized pneumatic system designed to optimize airflow, pressure control, and operational stability. Understanding tribupneu and its applications can significantly improve the performance of industrial processes.

Table of Contents

What Is Tribupneu?

Tribupneu is a term used to describe pneumatic systems that combine traditional air pressure mechanisms with tribological enhancements, which focus on friction reduction and wear control. In simpler terms, these systems are designed to ensure smooth operation of moving components while maintaining consistent air pressure and efficiency. Unlike conventional pneumatic setups, tribupneu integrates advanced materials, seals, and control mechanisms that reduce energy loss and extend the lifespan of equipment.

At its core, tribupneu functions by regulating compressed air to perform mechanical work. The system includes key components such as compressors, valves, actuators, and specialized pneumatic cylinders. However, what sets tribupneu apart is the emphasis on tribological efficiency, which minimizes friction, heat generation, and wear in moving parts. This combination results in higher operational reliability, lower maintenance costs, and enhanced safety standards.

How Tribupneu Works

The operation of a tribupneu system is based on the controlled flow of compressed air. Air is first compressed using an air compressor, which is then filtered to remove impurities and moisture. This clean, pressurized air is directed through valves that regulate flow and pressure. Actuators and cylinders convert the energy of the compressed air into mechanical motion, driving machinery or equipment.

Tribological enhancements in tribupneu systems play a critical role in ensuring smooth movement. Components are often coated with low-friction materials or treated with lubricants that resist wear. As a result, the system operates quietly, efficiently, and with minimal energy loss. This makes tribupneu particularly valuable in industries where precision and reliability are essential, such as automotive assembly, packaging, and heavy machinery manufacturing.

Key Components of Tribupneu

Understanding the components of tribupneu is important for anyone looking to implement or maintain these systems. The primary elements include:

- Air Compressors: These devices generate the compressed air needed for operation. Modern tribupneu compressors are energy-efficient and equipped with sensors to monitor performance.

- Valves and Regulators: Valves control the direction and flow of air, while regulators maintain consistent pressure levels. In tribupneu systems, these components are designed to minimize friction and prevent leaks.

- Actuators and Cylinders: These convert air pressure into mechanical motion. Tribupneu actuators are engineered with low-friction materials, which reduces wear and enhances precision.

- Filters and Lubricators: Filters remove contaminants, and lubricators ensure moving parts are well-lubricated, preventing damage and prolonging system life.

By combining these components with advanced tribological techniques, tribupneu systems achieve superior performance compared to traditional pneumatic setups.

Applications of Tribupneu

The versatility of tribupneu systems makes them suitable for a wide range of industrial and commercial applications. One of the most common uses is in manufacturing plants, where precision movement and consistent air pressure are essential. For example, assembly lines that require high-speed operation benefit from tribupneu’s low-friction mechanisms, which ensure smooth, uninterrupted motion.

In the transportation industry, tribupneu is used in pneumatic suspension systems for trucks, buses, and trains. These systems rely on compressed air to maintain stability and absorb shocks, providing a smoother ride and reducing wear on mechanical components. Tribupneu’s tribological enhancements ensure that suspension systems operate efficiently, even under heavy loads and varying environmental conditions.

Another important application is in packaging and material handling. Automated packaging machines often rely on pneumatic systems to move products quickly and accurately. Tribupneu systems improve performance by reducing friction in cylinders and actuators, ensuring faster operation and longer equipment life.

Table: Comparison Between Conventional Pneumatic Systems and Tribupneu

| Feature | Conventional Pneumatic | Tribupneu |

|---|---|---|

| Friction Control | Standard | Enhanced with tribology |

| Energy Efficiency | Moderate | High |

| Maintenance Frequency | Regular | Reduced |

| Noise Levels | Moderate to High | Low |

| Lifespan of Components | Shorter | Extended |

| Precision in Operation | Standard | High |

This table clearly demonstrates why industries are increasingly adopting tribupneu solutions for critical operations.

Benefits of Tribupneu

Implementing tribupneu systems offers multiple benefits for industrial operations. One of the primary advantages is improved energy efficiency. By reducing friction in moving components, tribupneu systems require less energy to operate, leading to lower electricity costs and a smaller environmental footprint.

Another key benefit is enhanced equipment longevity. Components that experience less wear require fewer replacements, reducing maintenance costs and downtime. This is particularly valuable in high-volume manufacturing environments where even minor interruptions can lead to significant financial losses.

Safety is also enhanced with tribupneu systems. Smooth operation and precise control minimize the risk of accidents caused by sudden movements or pressure fluctuations. In addition, the quieter operation of tribupneu systems contributes to a safer and more comfortable working environment.

Finally, tribupneu systems offer scalability and flexibility. They can be tailored to meet the specific needs of different industries, whether it’s high-speed automation, heavy-duty transportation, or delicate material handling. This adaptability makes tribupneu an ideal solution for both small-scale operations and large industrial facilities.

Maintenance and Troubleshooting

Despite their advanced design, tribupneu systems require proper maintenance to ensure optimal performance. Routine checks should focus on air filters, lubrication levels, and valve functionality. Inspecting actuators and cylinders for signs of wear is essential, as even minor friction issues can reduce efficiency.

Troubleshooting common problems in tribupneu systems typically involves checking for air leaks, pressure inconsistencies, and mechanical wear. For example, if a cylinder is moving slower than expected, it may indicate insufficient lubrication or a partially blocked air line. Regular maintenance schedules and timely replacement of worn components are key to prolonging system life and preventing costly downtime.

Future Trends in Tribupneu Technology

The future of tribupneu technology looks promising, with ongoing research focused on further reducing friction and enhancing system intelligence. Emerging trends include the integration of sensors and IoT connectivity, which allows real-time monitoring of pressure, flow, and wear levels. These advancements enable predictive maintenance, reducing downtime and improving operational efficiency.

Additionally, the development of eco-friendly materials for tribupneu components is gaining traction. Low-friction polymers and coatings not only enhance performance but also reduce environmental impact. As industries strive for sustainability, tribupneu systems are expected to play a critical role in energy-efficient and long-lasting pneumatic solutions.

Conclusion

Tribupneu represents a significant evolution in pneumatic technology, combining the principles of air pressure mechanics with advanced tribology to optimize performance, reduce friction, and extend equipment lifespan. From manufacturing to transportation, these systems provide reliable, energy-efficient, and precise solutions for modern industry. Understanding the functionality, applications, and benefits of tribupneu is essential for any business looking to enhance operational efficiency and reduce maintenance costs. With continued innovation and adoption, tribupneu is poised to become a cornerstone of industrial pneumatic systems, offering both technological and economic advantages.

By integrating tribupneu into operations, industries can enjoy smoother workflows, lower energy consumption, and improved safety, making it a practical and forward-looking choice for the modern industrial landscape.

FAQ Section About Tribupneu

What is tribupneu used for?

Tribupneu is used in industries requiring precise pneumatic control, including manufacturing, packaging, transportation, and material handling.

How does tribupneu differ from conventional pneumatics?

Tribupneu integrates tribological enhancements to reduce friction, increase efficiency, and extend equipment lifespan, unlike standard pneumatic systems.

Is tribupneu energy-efficient?

Yes, tribupneu systems reduce energy loss by minimizing friction, making them more energy-efficient than traditional pneumatic setups.

What industries benefit most from tribupneu?

Industries such as automotive, packaging, heavy machinery, and transportation benefit the most due to the need for precision, reliability, and durability.

How often should tribupneu systems be maintained?

Maintenance should be routine, focusing on lubrication, filters, valves, and actuators. The exact frequency depends on usage intensity and environmental conditions.

Can tribupneu be retrofitted into existing systems?

Yes, many tribupneu components are compatible with existing pneumatic setups, allowing for upgrades without full system replacement.