Key Takeaways:

- HEPA filters are essential in maintaining cleanroom air quality by capturing airborne contaminants.

- Proper installation and maintenance of HEPA filters are crucial for their effectiveness.

- Advancements in HEPA filter technology continue to improve cleanroom environments.

Table of Contents

- Understanding HEPA Filters in Cleanrooms

- The Role of HEPA Filters in Contamination Control

- Proper Installation and Maintenance of HEPA Filters

- Advancements in HEPA Filter Technology

- Integrating HEPA Filters with HVAC Systems

- Challenges and Considerations in HEPA Filter Implementation

- Future Trends in Cleanroom Air Filtration

- Conclusion

Understanding HEPA Filters in Cleanrooms

High-Efficiency Particulate Air (HEPA) filters are specifically designed to trap at least 99.97% of particles that are 0.3 microns in diameter, making them indispensable for cleanroom applications. In these tightly regulated environments, the potential for even microscopic airborne contaminants to disrupt sensitive processes highlights the importance of robust filtration systems. Proper HEPA filter installation, CA is crucial for maintaining optimal performance and ensuring regulatory compliance in these settings.

Cleanrooms must adhere to strict cleanliness standards, particularly in industries like pharmaceuticals and microelectronics, where particle contamination can lead to costly defects or compromised safety. Without effective filtration, contaminants can accumulate and jeopardize critical studies, manufacturing runs, and even patient health in healthcare environments.

The Role of HEPA Filters in Contamination Control

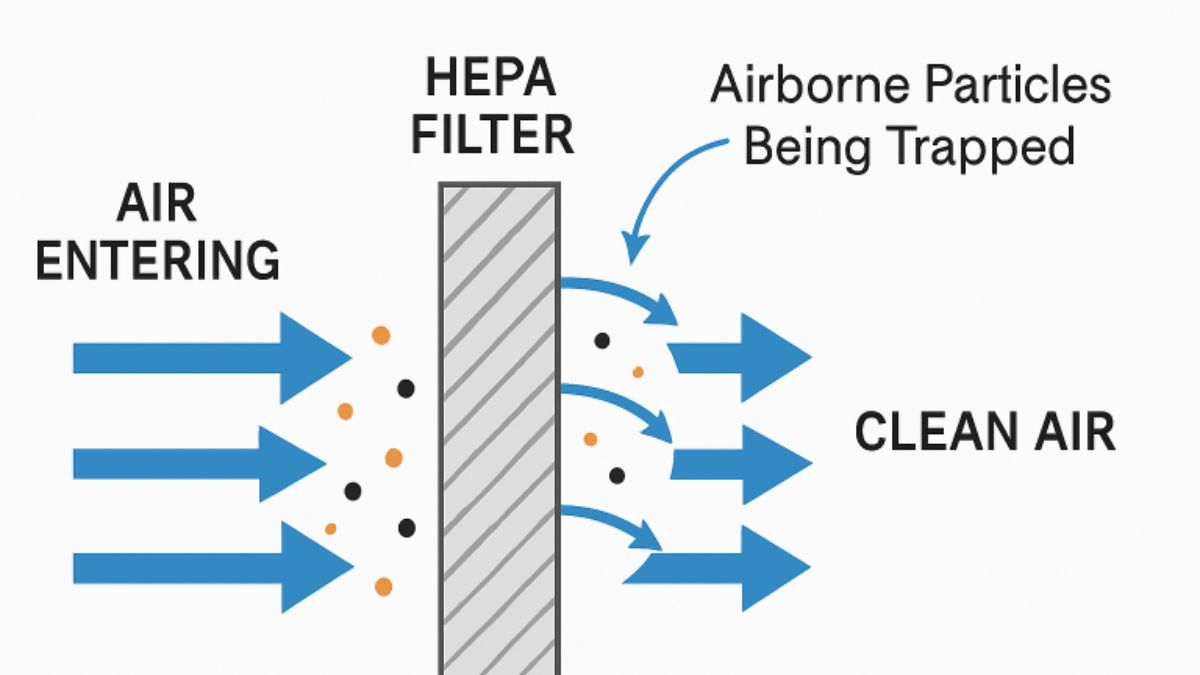

HEPA filters serve as both reactive and preventive barriers against airborne particles, including dust, spores, bacteria, and viruses. They are crucial in industries such as biotechnology and pharmaceuticals for safety and process integrity. By capturing contaminants before they settle or breach production lines, HEPA filters significantly lower risks of product recalls, rejections, or patient exposure. Their filtration involves fibrous layers trapping particles through interception, impaction, and diffusion. These mechanisms enable HEPA filters to trap particles across a wide range of sizes. For a detailed scientific understanding, the CDC offers extensive resources.

Proper Installation and Maintenance of HEPA Filters

Even the best HEPA filter can fail without proper installation and maintenance. Sealing integrity is crucial — gaps allow contaminants, compromising the cleanroom. Technicians must inspect filter housings, replace gaskets, and follow replacement schedules. Regular maintenance, inspections, and air particle monitoring support filter performance. Adhering to manufacturer and ISO standards ensures consistent filtration. Skipping maintenance risks product quality and increases costs due to energy use and filter aging.

Advancements in HEPA Filter Technology

Ongoing research in air filtration technology has yielded several meaningful advancements for cleanroom HEPA filters. Innovative materials, improved pleat designs, and enhanced support structures have made filters lighter, longer-lasting, and more energy-efficient. For instance, newer HEPA filters are being designed with nanofiber coatings that further enhance the capture of ultrafine particles while maintaining lower pressure drops, resulting in cost savings and improved sustainability. Advancements also extend to integrated filter status monitoring systems, which allow for real-time alerts on filter performance. Such smart monitoring capabilities enable facilities to stay ahead of issues and minimize unnecessary downtime.

Integrating HEPA Filters with HVAC Systems

Optimal cleanroom performance depends on integrating HEPA filters into HVAC systems, a process that is complex and requires careful calculations to ensure airflow, pressure, and filter placement are optimized, thereby preventing stagnation and uneven air velocities. A well-designed system ensures even air distribution and maintains optimal temperature and humidity, thereby supporting both comfort and process efficiency. Retrofitting HEPA filters can be challenging due to fan capacity and ductwork considerations, so consulting cleanroom HVAC professionals is essential for meeting high air quality standards.

Challenges and Considerations in HEPA Filter Implementation

HEPA filters offer benefits but pose challenges, such as increased pressure drop, which strains HVAC systems and raises energy costs. Key issues include filter compatibility, installation, monitoring, and replacement. Choosing the correct filters and maintaining seals prevents problems. Facilities should also consider lifecycle costs, striking a balance between air quality, sustainability, and efficiency. Proper planning, staff training, and staying updated on technology help manage these challenges.

Future Trends in Cleanroom Air Filtration

The future of cleanroom air filtration lies in greater automation, self-cleaning filter coatings, and the broader integration of digital monitoring into building management systems. Smart sensors and IoT-enabled devices are being developed to continuously assess air quality, detect filter saturation, and automate maintenance schedules. These trends promise to reduce manual labor, cut costs, and ensure even higher standards of environmental control. Researchers are also exploring novel filtration materials and configurations designed to further reduce resistance to airflow without compromising efficiency.

As air quality regulations become more stringent and industries place increasing value on both sustainability and operational uptime, the market for advanced HEPA solutions is expected to continue its rapid evolution.

Conclusion

HEPA filters stand at the forefront of cleanroom air quality control. When implemented with care — from correct specification and installation to ongoing maintenance and system integration — they reliably reduce airborne contamination, safeguarding the integrity of sensitive processes. With continuous technological advancements and a growing emphasis on automation and sustainability, the future of cleanroom filtration looks poised for even greater achievements, supporting critical research, manufacturing, and healthcare outcomes for years to come.