Key Takeaways

- Regular maintenance of electrical equipment is essential to prevent unexpected failures and minimize operational downtime.

- Implementing predictive maintenance strategies can lead to significant cost savings and enhanced equipment reliability.

- Training staff to recognize early warning signs and conducting routine inspections are critical components of an effective maintenance program.

Table of Contents

- The Importance of Regular Electrical Equipment Maintenance

- Common Causes of Electrical Equipment Failures

- Implementing Predictive Maintenance Strategies

- Routine Inspections and Condition-Based Monitoring

- Training Staff to Recognize Early Warning Signs

- Leveraging Technology for Maintenance Optimization

- Developing a Comprehensive Maintenance Plan

- Conclusion

The Importance of Regular Electrical Equipment Maintenance

Regular maintenance of electrical equipment is more than a best practice—it’s a business imperative for ensuring reliability and safety. Organizations that ignore routine inspections often face unplanned shutdowns and significant losses due to equipment failure. In fact, unexpected electrical faults can immediately halt production processes, placing both profitability and worker safety at risk. Companies that adhere to a structured maintenance approach see fewer interruptions and benefit from more consistent operations. For those seeking specialized assistance, services like https://divergentalliance.com/electrical-equipment-testing-refurbishing/ can provide expertise in equipment testing and refurbishment, offering valuable support for minimizing downtime.

Neglecting maintenance also comes with financial repercussions. When electrical systems fail, repair costs are typically higher, and there is also the loss of output during unexpected outages. According to a report by Sumitomo Drive Technologies, the average price of unplanned downtime for industrial manufacturers can reach up to $260,000 per hour, making proactive care a vital investment for any facility.

Properly maintained equipment helps companies comply with regulations and insurance requirements, reducing the likelihood of liability claims or safety violations. Reliable systems also protect staff and sensitive assets from the hazards associated with sudden electrical malfunctions.

Preventive actions have been proven to reduce both short-term and long-term costs. Whether in manufacturing, healthcare, or commercial settings, integrating maintenance programs strengthens an organization’s resilience against disruptive failures and fosters a culture of operational excellence.

Every business should prioritize a maintenance protocol tailored to its unique operational requirements. Regular reviews and updates of these practices help organizations adapt to evolving technologies, workloads, and risk factors. For more information on best practices and industry statistics, the Electrical Safety Foundation International provides a comprehensive resource for workplace safety data.

Common Causes of Electrical Equipment Failures

Identifying the causes behind electrical equipment malfunctions helps businesses implement more effective maintenance strategies and avoid costly interruptions. Some of the most common reasons for electrical failures include:

- Aging Equipment: Components deteriorate over time, often leading to insulation breakdown and compromised performance.

- Poor Maintenance: Skipping or delaying regular checks allows minor issues to grow into major faults.

- Human Error: Missteps during equipment operation or repair, such as incorrect installations or overlooked warnings, can trigger sudden failures.

- Environmental Stress: Excessive heat, humidity, dust, or vibration accelerates equipment wear, and power surges can overload vulnerable systems.

Understanding these risk factors and addressing them through consistent, scheduled maintenance significantly lowers the chance of downtime. According to the U.S. Department of Energy, implementing a predictive maintenance program can reduce breakdowns by up to 70% and lower overall maintenance costs by as much as 25%.

Implementing Predictive Maintenance Strategies

Predictive maintenance relies on real-time data to assess equipment health and anticipate issues before failures occur. By collecting operational information through sensors and diagnostic tools, companies can identify early warning signs and take action before they escalate into major outages. This approach keeps critical machinery running and decreases the likelihood of last-minute breakdowns during production runs.

The benefits of predictive maintenance are clear: it enables timely, targeted repairs, which minimize both scheduled and unscheduled downtime. Organizations also experience significant cost savings by extending the lifespan of their electrical assets and optimizing maintenance schedules based on the actual condition of the equipment, rather than relying solely on calendar dates. Moreover, this strategy enhances workplace safety by providing alerts about emerging hazards, giving maintenance teams more time to respond.

Major enterprises, such as Toyota, have reduced equipment breakdowns by over 70% by embracing predictive and AI-based maintenance systems, underscoring the tangible impact such strategies can have on operational efficiency.

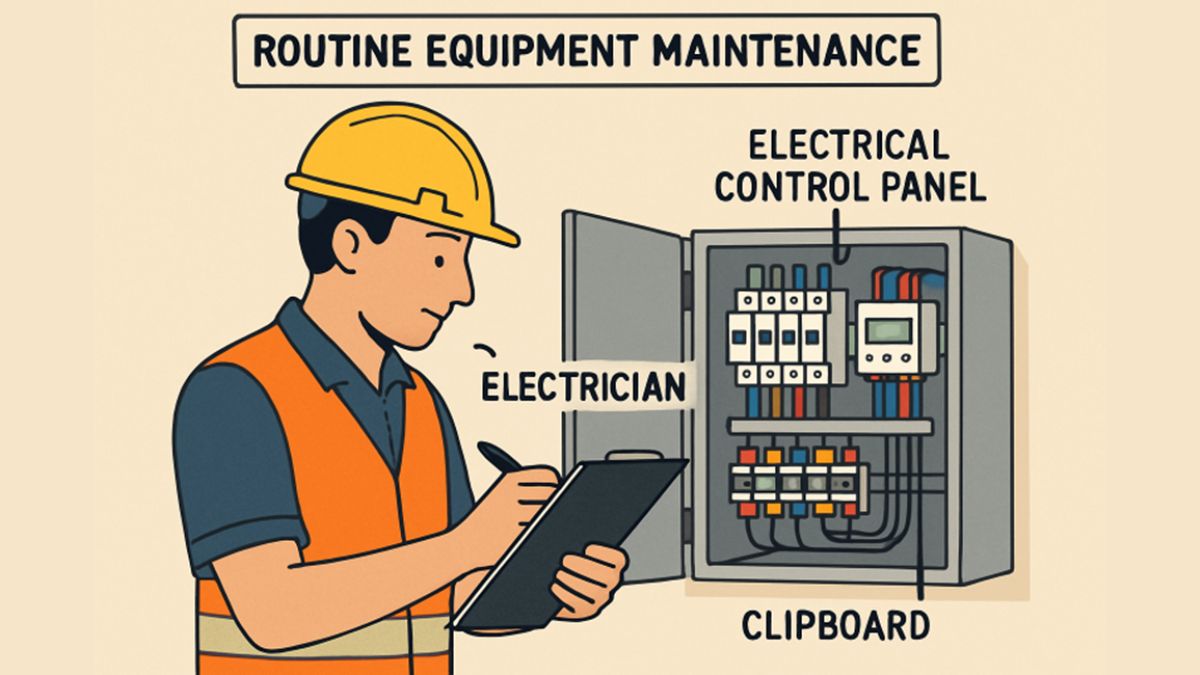

Routine Inspections and Condition-Based Monitoring

Routine inspections are the backbone of any effective electrical maintenance program. Key methods include:

- Thermal Imaging: Enables technicians to identify overheating, loose connections, and other flaws invisible to the naked eye.

- Insulation Testing: Discovers deteriorated wires and compromised protective barriers that could lead to electrical shorts.

- Vibration Analysis: Monitors moving components like motors and pumps for imbalance or wear.

Condition-based monitoring surpasses one-size-fits-all schedules by linking maintenance activities to the actual state of the equipment, resulting in optimized resource utilization and fewer disruptions.

Training Staff to Recognize Early Warning Signs

One often overlooked element of maintenance is staff training. Empowering workers with the ability to detect problems early—for example, strange noises, overheating, or unexpected shutdowns—can mean the difference between a quick fix and a prolonged outage. Practical training includes not only recognizing physical symptoms but also understanding the appropriate steps to take if a hazard is detected. Frequent refresher courses and hands-on drills keep teams prepared and responsive, ultimately safeguarding productivity and employee well-being.

Leveraging Technology for Maintenance Optimization

Technological innovations—such as IoT sensors, smart meters, and AI analytics—are transforming the way organizations manage their electrical assets. By continuously gathering and analyzing performance data, these solutions provide instant feedback about developing issues, allowing for rapid intervention. Companies leveraging these tools can move past traditional, rigid calendars to a dynamic, data-driven model that maximizes uptime. For instance, the Maintenance Index provides daily health scores for facilities, enabling informed decisions about when to perform specific maintenance tasks.

Developing a Comprehensive Maintenance Plan

To achieve maximum reliability and minimum downtime, organizations should build a maintenance plan that integrates:

- Regular Inspections: Calendar-based and reactive checks tailored to asset criticality.

- Predictive Maintenance: Utilizing continuous data collection to prevent foreseeable failures.

- Staff Training: Ongoing education in early detection and emergency response techniques.

- Technology Integration: Automated monitoring and analytics for real-time equipment insights.

Strategic planning should also include periodic evaluations of the program’s effectiveness, ensuring that the maintenance regimen evolves in tandem with technological changes and operational needs.

Conclusion

Mitigating costly downtime through systematic maintenance of electrical equipment is an investment in both safety and long-term profitability. When organizations understand the risks of failure, implement predictive technologies, promote condition-based monitoring, and train personnel to act quickly, they achieve superior resilience and operational stability. A comprehensive, proactive maintenance strategy remains the cornerstone for minimizing unexpected disruptions and ensuring continuous business success.