Table of Contents

- Enhancing Mobility and Maneuverability

- Reducing Physical Strain and Injuries

- Boosting Productivity Through Efficient Material Handling

- Protecting Flooring and Reducing Noise

- Ensuring Durability and Reliability

- Adapting to Industry-Specific Needs

- Integrating Smart Technology for Predictive Maintenance

- Conclusion

In today’s industrial and commercial workplaces, every operational detail can impact the bottom line. One of the most underrated components for driving workplace efficiency is the humble caster. The right caster wheels can enhance mobility, safety, and productivity, often delivering returns that far outweigh their initial investment. By understanding how these critical tools shape workflow dynamics, managers and facility designers can make smarter, more strategic decisions that benefit employees and infrastructure alike.

Casters serve as the bedrock of movement for everything from warehouse carts to medical equipment. High-quality casters enable the transport of heavy materials with less effort while also contributing to safer environments and increased operational uptime. When workplaces overlook the role of casters, they may inadvertently invite inefficiencies, downtime, or even workplace injuries—costly missteps in demanding industries.

When choosing casters, it is vital to think beyond upfront cost and consider factors like ergonomics, noise reduction, and suitability for specific floor types or industry requirements. Modern caster innovations now address these needs more effectively than ever, empowering businesses to raise the bar on productivity and employee well-being.

According to the U.S. Bureau of Labor Statistics, sprains and strains accounted for 41% of all workplace injuries and illnesses requiring days away from work in 2005.

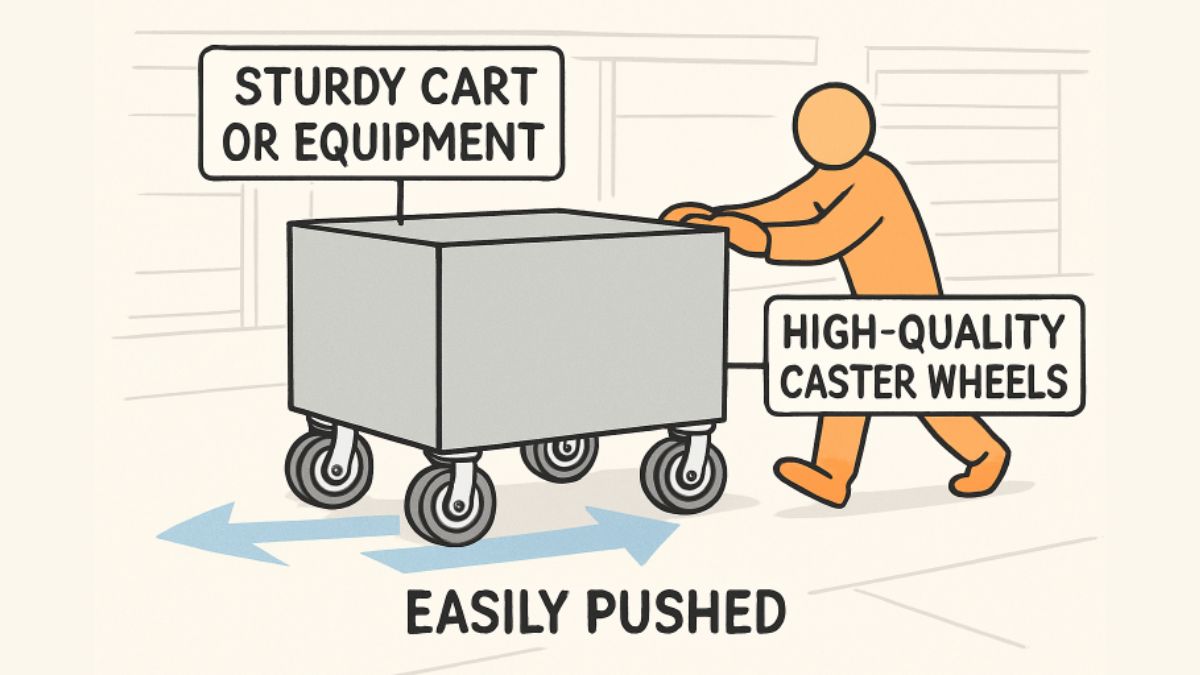

Enhancing Mobility and Maneuverability

High-caliber casters deliver remarkably smooth and responsive movement, enabling employees to transport pallets, machinery, and supplies with far less resistance. Swivel casters offer multi-directional motion, which proves invaluable in tight aisles and crowded shop floors. This versatility increases agility, enabling teams to reposition equipment rapidly and respond more nimbly to rapidly changing operational requirements. As a result, the overall workflow becomes more seamless and responsive, benefiting both output and worker morale.

Reducing Physical Strain and Injuries

Ergonomics plays an important role in workplace safety and employee satisfaction. Casters designed with precision bearings and shock-absorbing materials minimize the force workers must exert, directly reducing strains, sprains, and repetitive stress injuries. Over time, investing in ergonomic casters can help organizations lower absenteeism, decrease workers’ compensation claims, and retain a healthier, more productive workforce.

Boosting Productivity Through Efficient Material Handling

Efficient material handling relies on the ability to swiftly and safely move products through every stage of the supply chain. Selecting casters rated for specific load tolerances and environments ensures that carts and machinery perform predictably on different surfaces and under varying weights. Advanced options, such as motorized casters, can further enhance productivity, particularly in settings where oversized loads are common and manpower is at a premium. With reduced manual labor, employees can focus on value-added tasks, driving higher output for the organization.

For more insights on improving industrial efficiency, IndustryWeek offers practical strategies for optimizing material-handling operations.

Protecting Flooring and Reducing Noise

The right caster selection not only enhances movement but also preserves the longevity of facility flooring. Softer wheel materials such as rubber and thermoplastic are ideal for delicate or noise-sensitive areas, while hard wheels are better suited for rough, industrial surfaces. Noise reduction is a core concern in healthcare and office environments; quieter casters help maintain a calm atmosphere and can even improve concentration and the quality of patient care.

Ensuring Durability and Reliability

A high-quality casters can withstand harsh treatment—ranging from chemical exposure to rapid temperature fluctuations—thanks to robust materials such as polyurethane and reinforced nylon. By installing reliable casters, organizations minimize breakdowns and unplanned downtime, keeping operations on track and slashing routine maintenance costs.

Adapting to Industry-Specific Needs

Various industries have specialized mobility requirements. For example, food service and pharmaceutical industries rely heavily on stainless-steel, non-corrosive casters that are both hygienic and easy to clean. In contrast, manufacturing sectors may prioritize shock absorption or chemical resistance. Matching caster specifications to regulatory and performance requirements improves compliance and in-field performance, supporting safer, more effective operations.

Integrating Smart Technology for Predictive Maintenance

Recent advancements in smart technology have extended to casters, enabling sensor integration that tracks load, movement, and environmental factors. These sensors empower organizations to implement predictive maintenance, addressing wear and tear before it disrupts operations. In large or complex facilities, smart casters can identify high-traffic patterns and bottlenecks, informing layout adjustments and resource planning for even greater efficiency.

Conclusion

Quality casters are vital links in the chain of industrial efficiency. From boosting maneuverability and protecting employees to guarding valuable infrastructure, high-grade casters are a strategic investment that yields long-term gains. Facility managers who recognize and act on the importance of selecting the best casters will promote not just workplace productivity but also employee well-being and resource savings, further cementing their organization’s competitive edge. For businesses seeking compliant, modern workplaces, the importance of casters should never be overlooked.