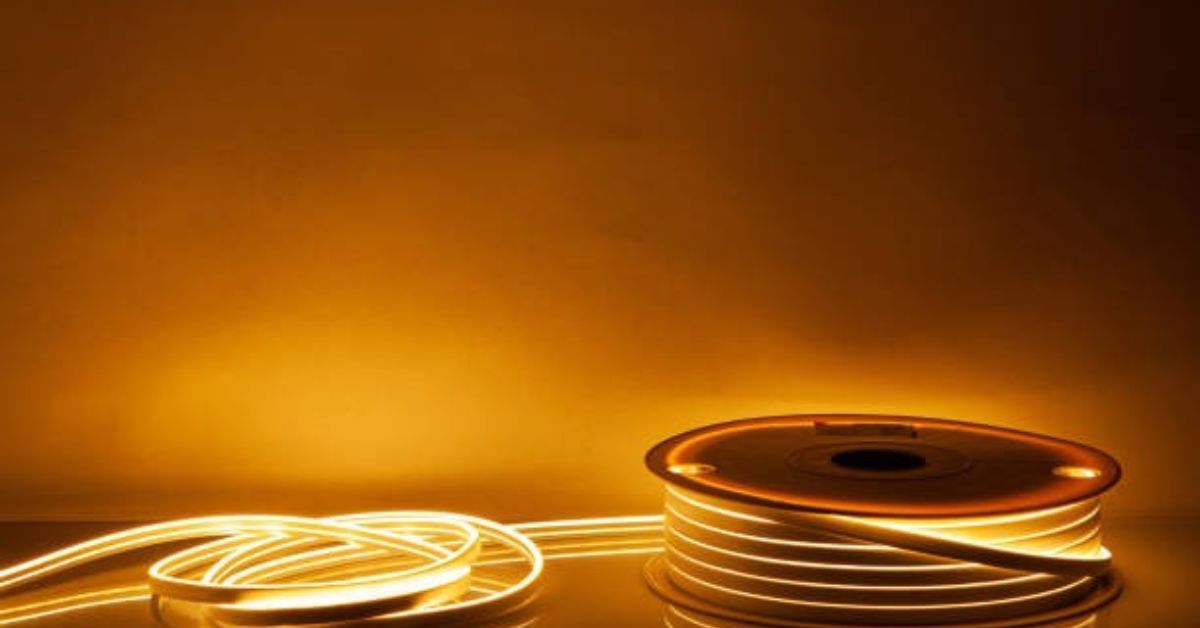

The LED lighting industry has experienced a major transformation in recent years, driven by innovative technologies such as COB LED Strips. COB, or Chip on Board, technology provides a continuous and uniform line of light, eliminating the dot effect seen in traditional LED strips. These strips have become a favorite for designers, architects, and contractors who seek seamless, professional-quality lighting for both residential and commercial applications.

Behind this innovation are dedicated LED Strip Lights Factories, which produce high-quality COB LED strips in bulk while ensuring consistent performance, durability, and energy efficiency. The collaboration between cutting-edge technology and factory expertise has made modern lighting more versatile, visually appealing, and reliable.

The Advantages of COB LED Strips

COB LED strips offer several benefits that distinguish them from standard SMD LED strips:

Uniform light output: Provides a smooth, dot-free appearance.

High brightness: Multiple LED chips closely packed create intense illumination.

Energy efficiency: Brighter light with lower power consumption.

Long lifespan: Advanced heat dissipation ensures durability.

Flexible design: Can be bent or shaped for curved and intricate installations.

These advantages make COB LED strips ideal for premium projects such as architectural lighting, high-end retail displays, hospitality environments, and creative residential installations.

The Role of LED Strip Lights Factories

An LED Strip Lights Factory ensures that each product meets strict quality standards from start to finish. These factories combine advanced machinery with expert engineering to produce large volumes of consistent, reliable LED strips. Key production processes include:

Chip placement: High-quality LEDs are mounted accurately onto flexible PCBs.

Encapsulation: Protective coatings guard against moisture, dust, and UV damage.

Color and brightness calibration: Ensures uniform light across all strips.

Cutting and packaging: Pre-cut lengths and rolls for easy installation.

Rigorous testing: Voltage stability, heat management, and light quality are verified.

By maintaining these standards, factories support the growing demand for COB LED strips and other modern LED products worldwide.

Applications of COB LED Strips

COB LED strips are widely used across various industries due to their high-quality output and flexibility:

Architectural lighting: Seamless illumination of ceilings, walls, and facades.

Retail spaces: Highlighting products with consistent, high-quality light.

Hospitality: Hotels, restaurants, and event spaces benefit from elegant, even lighting.

Residential installations: Creating ambient lighting in kitchens, living rooms, and home offices.

Creative projects: Stage design, exhibitions, and decorative applications.

These strips allow designers to create stunning lighting effects without visible light dots or uneven brightness.

Benefits of Bulk Production and Factory Expertise

LED strip lights factories play a critical role in providing bulk solutions for businesses and contractors. Bulk purchasing and factory support offer:

Cost efficiency: Lower per-unit prices reduce project costs.

Consistent quality: All strips have uniform brightness, color, and performance.

Scalability: Large orders are easily fulfilled without delays.

Customization options: Factories can provide tailored lengths, voltages, and packaging.

Reliable delivery: Ensures that projects remain on schedule.

Bulk production ensures that contractors, distributors, and designers can complete large projects efficiently while maintaining high standards.

How COB LED Strips Enhance Lighting Design

COB LED strips offer design advantages that allow for creativity and innovation:

Smooth continuous light: Ideal for cove lighting, under-cabinet lighting, and indirect illumination.

Minimal glare: Reduces harshness for residential and commercial settings.

High color rendering: Enhances the appearance of colors in retail and hospitality spaces.

Flexible application: Can be integrated into curved structures, corners, or complex architectural features.

These features make COB LED strips a preferred choice for projects where lighting quality and visual appeal are critical.

Trends Shaping Modern LED Strip Production

Modern LED strip factories and COB technology have adapted to current market trends, including:

Smart integration: LED strips compatible with remote controls, apps, and smart home systems.

RGB and tunable white options: Dynamic lighting for customizable ambiance.

Advanced thermal management: Ensures longer lifespan and consistent performance.

Waterproof and dustproof designs: Suitable for both indoor and outdoor use.

Energy-efficient manufacturing: Reduced power consumption with eco-friendly processes.

By embracing these trends, factories ensure that COB LED strips remain at the forefront of modern lighting solutions.

Energy Efficiency and Sustainability

COB LED strips are highly energy-efficient, delivering bright and uniform lighting while consuming less electricity than traditional light sources. Their longer lifespan reduces replacement frequency, contributing to sustainability.

LED strip factories increasingly adopt eco-friendly practices, including:

Using recyclable materials and packaging

Optimizing production to minimize energy consumption

Reducing waste through precise manufacturing techniques

These practices support environmental sustainability while providing cost-effective solutions for businesses and homeowners.

Why Reliable Factories and Suppliers Matter

Working with experienced LED strip factories ensures:

High-quality products: Consistent performance across all batches.

Compliance with safety standards: CE, RoHS, and UL certifications.

Customization options: Strips tailored to project requirements.

Efficient supply chain: Bulk orders delivered on time to meet deadlines.

Technical support: Assistance with installation and troubleshooting.

Reliable factories and suppliers are essential for delivering professional-quality LED lighting systems that meet modern design standards.

FAQs

1. What is the main advantage of COB LED strips?

They provide uniform, dot-free lighting with high brightness and energy efficiency.

2. Can COB LED strips be used outdoors?

Yes, waterproof and weather-resistant versions are available for exterior installations.

3. Why purchase LED strips from a factory?

Factories ensure consistent quality, bulk availability, and customization for various projects.

4. How long do high-quality COB LED strips last?

With proper installation, they can last 30,000–50,000 hours.

5. Are COB LED strips energy-efficient?

Yes, they provide bright, continuous lighting while consuming less electricity.

Conclusion

COB LED strips, combined with the expertise of professional LED Strip Lights Factories, are transforming modern lighting. By providing smooth, uniform illumination with high energy efficiency, these products meet the demands of designers, architects, contractors, and homeowners alike.Partnering with trusted suppliers ensures access to COB LED Strips and bulk orders that maintain consistent quality and performance. The combination of advanced technology and factory expertise allows for innovative, sustainable, and visually stunning lighting solutions across residential, commercial, and industrial projects.